In today’s competitive market, manufacturing efficiency, quality, and innovation are more important than ever. One of the key methods to achieve these objectives in various industries, from automotive to consumer products, is through plastic injection moulding. Partnering with a top plastic injection moulding company can significantly benefit your business in several ways. Here’s why.

Expertise and Experience

A leading plastic injection moulding company brings extensive expertise and experience to the table. These companies have spent years, if not decades, perfecting their craft, working with diverse materials, and overcoming complex engineering challenges. Their knowledge can help you avoid common pitfalls, ensuring that your products are of the highest quality and meet industry standards.

Cost Efficiency

Investing in your own plastic injection moulding capabilities can be prohibitively expensive, especially for small to medium-sized enterprises. Equipment, maintenance, training, and raw material costs add up quickly. By partnering with a specialized company, you can leverage their economies of scale and save on the overheads, translating to lower production costs and more competitive pricing for your products.

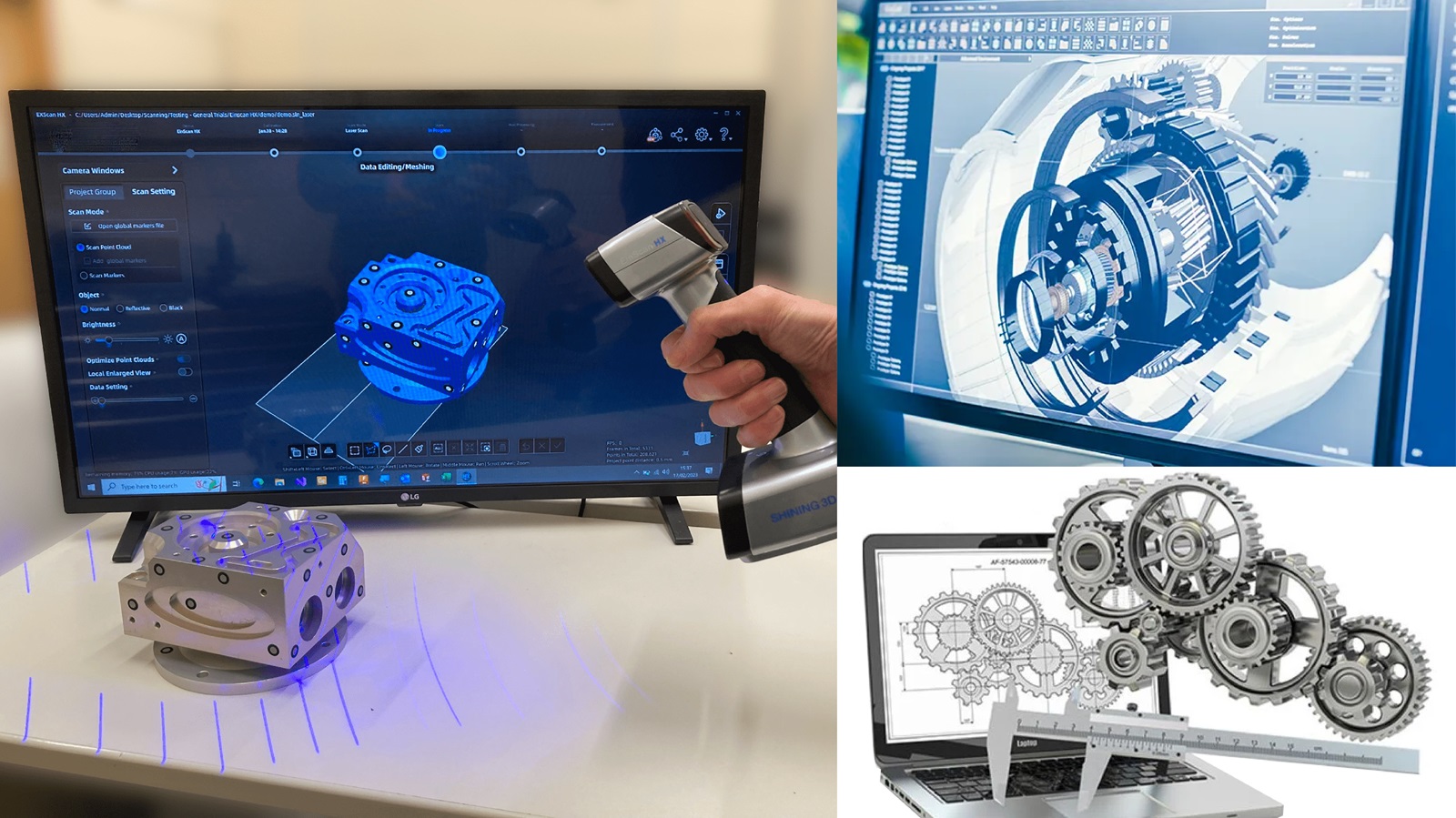

Advanced Technology and Innovation

Top plastic injection moulding companies stay at the forefront of technology and innovation. They invest in the latest machinery and software, continually improving their processes and capabilities. This commitment to innovation means they can offer advanced solutions, like high-precision moulds and complex material formulations, giving you a competitive edge in the market.

Speed to Market

In today’s fast-paced world, speed to market is critical. Working with a seasoned plastic injection moulding company can significantly shorten your product development cycle. With their advanced tooling and production capabilities, these companies can quickly turn designs into prototypes and scale up to full production, helping you meet demand and seize market opportunities.

Quality and Consistency

Quality and consistency are the hallmarks of a top plastic injection moulding company. They have stringent quality control processes in place, from raw material inspection to final product testing, ensuring that every part meets your specifications and industry standards. This reliability helps build trust with your customers, enhancing your brand reputation and loyalty.

Sustainable Practices

Sustainability is increasingly important in today’s business landscape. Leading plastic injection moulding companies are committed to environmentally friendly practices, such as using recycled materials, minimizing waste, and optimizing energy consumption. Partnering with such a company can improve your own sustainability credentials, appealing to environmentally conscious consumers and stakeholders.

Customization and Flexibility

Every business has unique needs, and a top plastic injection moulding company understands this. They offer customized solutions tailored to your specific requirements, whether you need a particular material, color, finish, or performance characteristic. This flexibility ensures that the final product aligns perfectly with your vision and business goals.

Strategic Partnership

Finally, when you partner with a top plastic injection moulding company, you’re not just getting a service provider; you’re gaining a strategic partner. These companies work closely with you throughout the product life cycle, offering insights, advice, and support to help you succeed in the market.

Conclusion

In conclusion, partnering with a top plastic injection moulding company offers numerous advantages, from cost savings and advanced technology to quality assurance and strategic collaboration. These partnerships can drive innovation, enhance competitiveness, and support sustainable growth. In today’s dynamic business environment, choosing the right plastic injection molding partner can be a game-changer for your company.