Pipe cutting, as the name suggests, is onsite machining that cuts pipes to make sure they are ready for welding to be connected to new pipes. It likewise helps administration a cold pipe cutting and bevelling machine. We utilize cold slicing procedures to guarantee work can be completed in a fire resistant setting during plant upkeep or closure. Viewed as a completing task, inclining is the cycle that assists the line with being ergonomically situated to be associated with another line. It changes the sharp-sliced open edges to a smoother edge for more secure dealing with.

Precision and efficiency

Our services use state-of-the-art automated beveling instruments that reliably yield precise and accurate results while saving a significant amount of job time. This guarantees a simplified and effective procedure. Our cold pipe cutting and beveling services, which we provide through our highly qualified team and relationships with prestigious international brands, are supported by cutting-edge technologies and a lot of knowledge. Every cutting and beveling activity is more accurate and reliable with the automated procedure.

Equipment’s

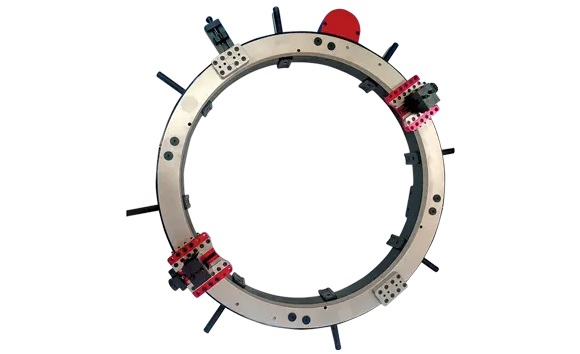

The Excalibur is outfitted with a two-speed drive gearbox, which positively develops the machine around the line in a wide range of line-cutting circumstances. No out-of-round compensation is required, as the machine follows the pipe’s external width, delivering an even and reliable cut. The drive chain can be abbreviated or extended to oblige pipes from as little as 6 crawls up to 5m in distance across vessels and then some.

Workplace safety

Our top goal is to make sure our service professionals and supervisors are safe. We make sure supervisors understand how to handle injuries and fires that may occur from on-site machining dangers. For instance, working at heights and in cramped areas might result in accidents; determining the risk and implementing the necessary precautions will guarantee that the task is completed quickly and safely. A well-maintained tool lowers the possibility of malfunction. To ensure optimal production, we check and calibrate our pipe cutting and beveling tools on a regular basis.

Cost savings

The utilization of mechanized devices guarantees accuracy and converts into huge time and cost reserve funds by speeding up the cutting and inclining processes. Our approach to decreasing labor and executing cold slicing methods straightforwardly contributes to a more secure working environment, encouraging a safe and mishap-free climate for both faculty and resources. Taking special care of the interesting requirements of desalination plants, our administrations incorporate capable line cutting off and angling, adding to the productive activity of these basic offices.

Cost of automatic pipe cutting machine

The cost of an automatic pipe cutting machine price in India right now To find out more about the different delivery choices for the automatic pipe cutting machine, go to the website and conduct a product search. The fastest-growing production expense in today’s society is the development of human resources. It is the forerunner and leader in laser industrial applications in India as well as the reliable source of solutions for worldwide laser processing. The machine can handle the remaining tasks.