Some of the parameters used in the extruder are important. Especially when it comes to determining the calibrated flow filament while printing. The correct settings guarantee that the printer ejects the appropriate amount of filament down to the nozzle. Without any complications of under-extrusion, over-extrusion, or failure of the print job. In this article, we will discuss some important ideas about this. This is necessary to make sure that the calibration of your extruder will consistently provide high-quality prints.

Importance of Extruder Calibration

The extruder calibration would have a direct impact on the quality of the printed object. Some problems include wrong layer joints, flimsy prints, or bulges on the surface of the print. Tuning the extruder helps regulate the feeding of the filament to ensure an appropriate flow rate. On which one can build a basis for a good print. Frequent calibration is helpful if you switch between different filaments or producers. Because various materials act differently.

Steps to Calibrate Extruder Settings

The extruder is an important part of a 3D printer, and its settings have to be calibrated always. Here are the steps on how to do it.

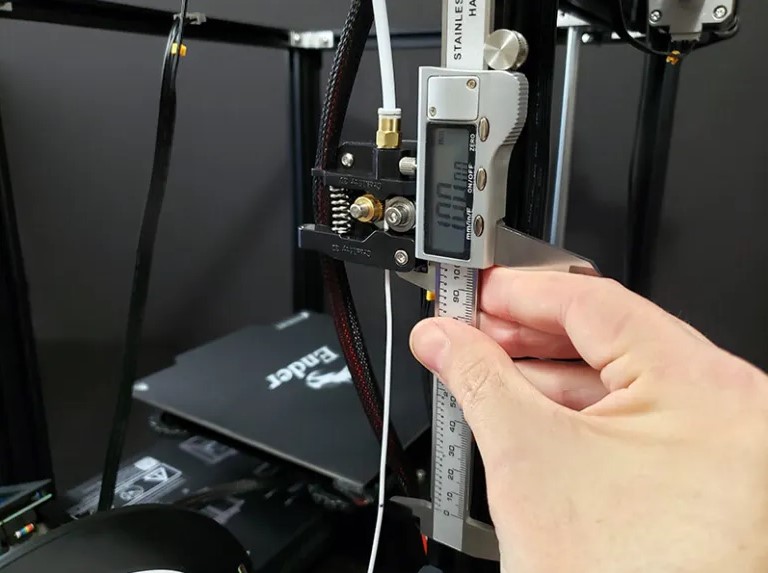

Measure and Adjust E-Steps

The first step for calibration of the extruder involves measuring a very important set of parameters. These are known as E-steps that represent the amount of filament being extruded by the extruder motor. Begin with the identification of a specific area. Start it with a distance of 100 mm from the extruder intake area as the starting point of the filament. Place the extruder and pass one hundred millimeters of filament through it and then measure the distance that will remain. If it is anything less than 100 mm, the user might need to tweak the E-steps. In either the firmware or software of the printer. Continue the process over and over until you get the right extrusion required for the diner.

Fine-Tuning Flow Rate

Once you have lowered the E-steps, you can then adjust the flow rate. It is done for better operation of the printer and proper supply of filament on the extruder. Print a single-layer test pattern to make sure it accurately represents what the final product will look like. And take the thickness of the extruded filament. Check out if the layers are as thick as they should be. If not, try to adjust the flow rate in the slicer software. This fine-tuning proves helpful in attaining the right measure of interaction with the print head.

Temperature Settings

Extrusion temperature greatly influences the flow of filament. These changes occur because various materials used need temperatures of different levels to control the flow rates. In general, PLA extrudes well at temperatures ranging between 190 and 220°C. While ABS extrudes between 220 and 250°C. Set the temperature as per the filament manufacturer’s instructions and print two prototypes in a different layer. It is important to determine the correct temperature for gliding through the nozzle.

Utilizing Enclosures for a Stable Printing Environment

When it comes to its usage, people have to ensure that they use the enclosures most appropriately. It is necessary to provide a stable ground for the printing. Besides all the requirements to obtain consistent extrusion, it is very important to manage the printing environment. There is the Prusa XL Enclosure, which is created specifically for the printer. This enclosure ensures that the temperature of the surrounding printer does not fluctuate. It is used to maintain an optimum temperature for the effective functionality of the printer. The design of the Prusa XL Enclosure ensures they regulate the environmental conditions of the printer. Thus, the filament flow is optimized and printing quality is improved. Especially for temperature-sensitive filaments.

Conclusion

It is essential in the extruder to set appropriate parameters. It helps to get proper flow and good prints in 3D printers. By using E-steps to calibrate, the flow rate to set, and the extrusion temperature should be set right. The use of the right printer enclosure can enhance print reliability and quality. Based on the fact that it controls the space within which the printer operates. It is essential to take time and troubleshoot any issue that may arise so that you can fix it correctly. This is because 3D prints can be very successful if often calibrated and leaned much on details.